| Type: 1/4 Ton 4x4 Truck Government Number: G503 Model: GPW Manufacturer: Ford Motor Company Date of Delivery: 30 September 1942 Serial Number: 69289 Hood Number: 20154290* |

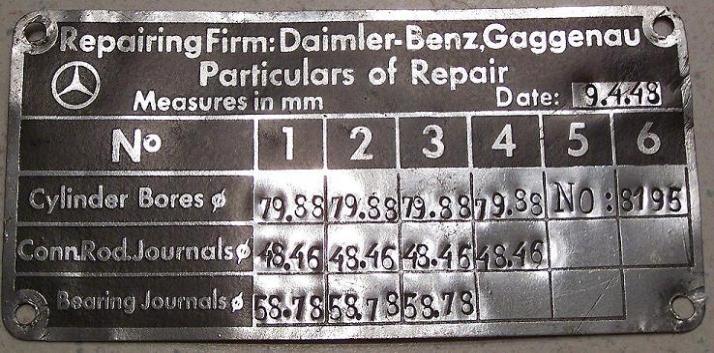

| Engine, above left photo. This is a view of the engine rebuild data plate prior to removal. The aluminum plate was riveted to the driver's side of the engine with copper rivets. Engine Rebuild Plate, above right photo. This is a close up of the data plate after removal, restoration and repainting. This engine was rebuilt on April 9th 1948. Note that all of the rebuild sizes are metric. |

| A BRIEF HISTORY OF THE FORD AND DAIMLER-BENZ CONNECTION |

| Ownership of the “Jeep“ name: |

| July 1941: Willys Overland and Ford Motor Company start production of a standardized ¼ Ton vehicle known as the Willys MB and Ford GPW. 1945: Willys MB and Ford GPW production ends. Post-War 1945: Willys Overland starts production of the “CJ” family or Civilian Jeep. 1953: Willys Overland Motor company is purchased by The Kaiser-Jeep Corporation. 1970: The Kaiser-Jeep Corporation is purchased by American Motor Company (AMC). 1982: AMC and Renault merge. 1987: AMC is purchased by Chrysler Motor Company. 1998: Chrysler and Mercedes Benz merge to form Daimler Chrysler. |

| DAIMLER BENZ in Gaggenau after 1945 |

| Saturation bombings of the various Daimler-Benz plants had been most effective during the Second World War - sixty years of that company's history lay in ruins. The truck facility at Gaggenau was 80% lost. Management and worker alike sorted through the rubble to salvage what was left. Enough was found to establish a modest repair facility, and in 1946, limited production of the prewar 170V Truck was resumed. Lack of funds however, severely limited activities (less than 600 of the 170V's were built before the currency reform of 1948). In 1951 production of the famous UNIMOG truck moved to Gaggenau. |

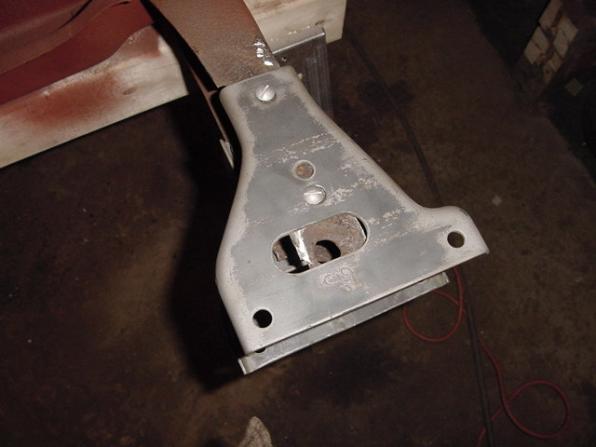

| Reproduction front Bumper Gussets being added, above left photo. The original gussets were not able to be salvaged. This view is from the bottom of the frame. Note the "F" marks on these reproductions. Although nicely marked, the small "F" will be hidden by the bumper. Underside of frame, passenger side, behind motor mount, above right photo. Many GPW's have this type of corrosion due to mud and water collecting in the bottom of the frame rails. |

| Another view of the passenger side frame corrosion, above left photo. Reproduction GPW rear cross member being added, above right photo. The original cross member had been bent so badly that it could not be salvaged. This vehicle was used on a farm after World War Two and several modifications had been done to the frame. These have all been removed and corrected. The rear spring shackles have been removed in this photo. |

| GPW Glove Box Door with Data Plates, left photo. This is the GPW glove box after sand blasting and priming, but prior to final painting and riveting of the data plates. Glove Box Door Push Button Latch, above right photo. This style of latch was introduced between May and June 1942 and used throughout the duration of GPW production. |

| Original brass Ford "Shift Plate", left photo. This style of plate was used from the beginning of GPW production through late 1942. Original steel Ford "Delivery Plate", right photo. Note that the servicing organization is the "QUARTERMASTER CORPS". This was changed to the "ORDNANCE DEPARTMENT" on vehicle plates after December 3rd 1942. This type of plate was used on GPW's from late 1942 until 1944. |

| Original brass Ford "Caution Plate", above photo. This style of plate was used from the beginning of GPW production through late 1942. Note the early Transfer Case High Range speed of 65 M.P.H. Later "Caution Plates" reduced this speed to 60 M.P.H. |

| GPW 69289 Overseas Service: |

| Rear End Rebuild Plate, above left photo. When 69289 was disassembled for restoration a data plate was found on the rear end housing (shown restored in red oxide primer, left photo). The data plate is marked: OBS 1 PBS 3 1 29 45 This translates to: Ordnance Base Shop 1 Peninsular Base Section 3. This rear end was rebuilt on January 29th 1945. OBS 1 PBS 3 was located in Pisa, Italy in January 1945. Ordnance Base Shops (OBS) rebuilt all types of equipment. The photo to the left is a M-1 Garand Barrel. The barrel is factory marked: D35448-I6-R 103 This barrel is a replacement that was installed on a war weary M-1 Garand. When the barrel was replaced, the OBS hand stamped it: RBLT. O.B.S.3 13. 6. 45 |

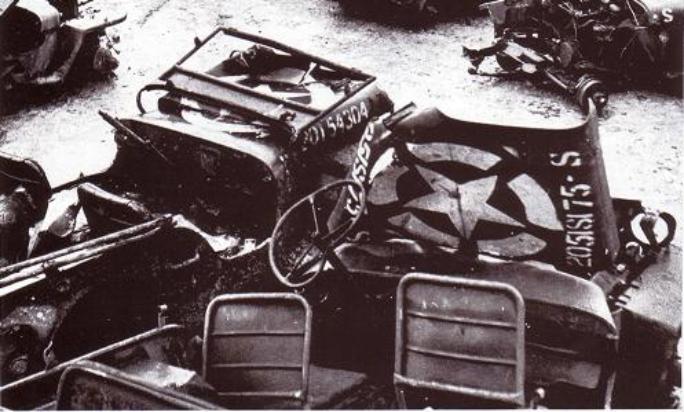

| The hood number for GPW 69289 mathematically should be 20154290. This is based on Ford GPW production numbers relative to the U.S. Army registration numbers assigned to that group of vehicles. Not all vehicles were accepted in sequential order. Some vehicles were used for testing by the factory, and others had production flaws and were accepted later. These vehicles were not assigned a registration number, so there are gaps in the mathematical process. The GPW (in the left photo) has a hood number of 20154304, mathematically 14 numbers from the proposed hood number of GPW 69289. This photo was taken of a vehicle salvage yard in France, late 1945. |

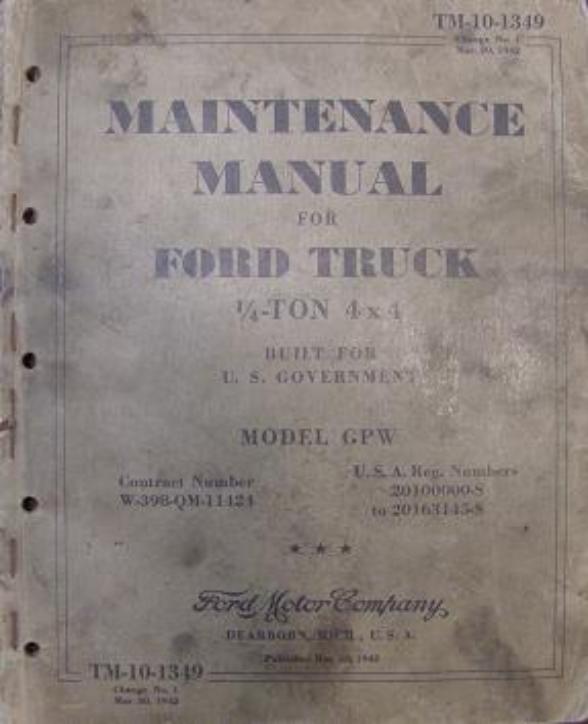

| Parts Manual TM-10-1348 Change No. 1 April 10 1942, above left photo. Maintenance Manual TM-10-1349 Change No. 1 March 30 1942, above right photo. These two manual are would have been issued with GPW 69289. Both are for Ford Contract Number W-398-QM-11424 U.S.A. Registration Numbers 20100000 to 20163145. |

| Passenger side frame rail with corrosion removed, above left photo. The entire passenger side inner frame rail was removed due to extensive corrosion. The area where the rear front spring shackle and motor mount were mounted have also been removed. The inside of the outer frame rail was strengthened with the addition of steel plate while the inner frame was removed. Replacement inner passenger side frame rail, right photo. The inner passenger side frame rail and motor mount were salvaged from the frame of GPW 106652 for use on GPW 69289. The rear front spring shackle was reused from GPW 69289. |

| Restored passenger side front frame, left photo. Reproduction "F" marked GPW bumper, "F" marked bumper gussets and spring shackle added. The bumper gussets and spring shackle have been correctly welded to the front frame. The bolts mounted on the bumper and spring shackle were added ONLY for welding and alignment. These will be removed prior to full restoration. Replica bumper gusset and spring shackle rivets, above right photo. These replica rivets were specifically designed to replicate the original rivets in the bumper gusset area. When torqued down, the round end cap will sheer off simulating a factory applied rivet. The four longer rivets on the bottom are for the spring shackle area. |

| Reproduction GPW rear cross member being added, above left photo. The rear cross member has been properly welded to the rear of the frame. Reproduction spring shackle prior to welding (note arrow marks for proper length of factory weld). Replica spring shackle and cross member rivets, above right photo. These replica rivets were specifically designed to replicate the original rivets on the spring shackles and cross member. When torqued down, the round end cap will sheer off simulating a factory applied rivet. All four rivets are the same length. |

| GPW 69289 before restoration, left photo and after restoration, right photo. The entire frame has been coated in red oxide primer to prohibit flash rusting prior one final media blasting. The reproduction GPW front bumper, bumper gussets, front and rear spring shackles and rear cross member have been fitted and welded in this picture. Passenger side frame with motor mount has been re-welded and riveted in place to match factory production specifications. M-31 Machine Gun Frame Mounts have been mounted and welded to the frame. |

| M-31C Nomenclature Plate and Gun Pedestal Frame Mounts, above photo. when using the M-31 Pedestal due to the recoil of the gun. Special mounts had to be added to the frame of the MB/GPW This modification was not done at the factory but rather by ordnance units in field depots. M-31 Machine Gun Mount, left picture. Pictured here is the M-31 Machine Gun Pedestal, Cradle and M-1919A4 .30 Caliber Machine Gun. Note the front leg is not currently attached in this photo. This M-1919A4 Machine Gun is a BATFE compliant non-gun with a dummy right side plate and no internal working parts. |

| .30 Caliber D38571 Ammunition Box, above left and right photo. The D38571 .30 Caliber Ammunition Box was specifically designed to be permanently mounted to the side of the M-1919 Machine Gun. This box held 250 rounds of belted Ammunition. Picture here is the early style cloth non-disintegrating style belt holding .30 caliber ammunition. This belt is loaded with one tracer round for every four ball rounds. This ammunition box will be mounted on the M-1919A4 Machine Gun pictured above. |

| Front view of 69289, above photo. GPW 69289 was produced under the Sixth Ford Contract - Number W-398-QM-11424. This was the 54,289th vehicle produced under this contract of 63,146 GPWs. GPW 69289 was accepted on September 30th 1942. 7,688 GPWs were produced in the month of August 1942, the seventh highest production month of 1942. The cost for each GPW in this contract was $925.00. GPW 69289 is believed to have been produced at the Ford factory in Dallas, Texas. |

| GPW 69289 Frame, above photo. Once the frame had been fitted with replacement sections and the front bumper and transmission cross member had been fitted for final alignment the frame was crushed glass blasted one final time prior to final painting with red oxide primer. |

| GPW 69289 Front Bumper Gusset, above left photo. The reproduction front bumper gussets have been correctly welded to the frame and the alignment bolts have been removed. The replica bumper gusset rivets have not been added in this photo. The script "F" will be hidden once the front bumper is mounted. GPW 69289 Frame Marking, above right photo. The frame marking on this GPW is stamped directly in front of the drivers side motor mount bracket. This stamping is barely visible in the photo, but GPW 69289 is stamped on the top of the frame directly next to the brake line bracket. |

| GPW 69289 Rear Cross Member, above left photo. The reproduction GPW rear cross member and spring shackle after being correctly welded to the frame, above left photo. Machine-gun mounts, above right photo. The special mounts after being correctly welded to the frame, above right photo. This modification was not done at the factory but rather by ordnance units in field depots. |